This website uses cookies

This website uses cookies. For further information on how we use cookies you can read our Privacy and Cookie notice

This website uses cookies. For further information on how we use cookies you can read our Privacy and Cookie notice

In stock

Shipped from abroad

Free return within 15 days for all eligible items.Details

Better service

96%Seller Score

53 Followers

Shipping speed: Good

Quality Score: Excellent

Customer Rating: Excellent

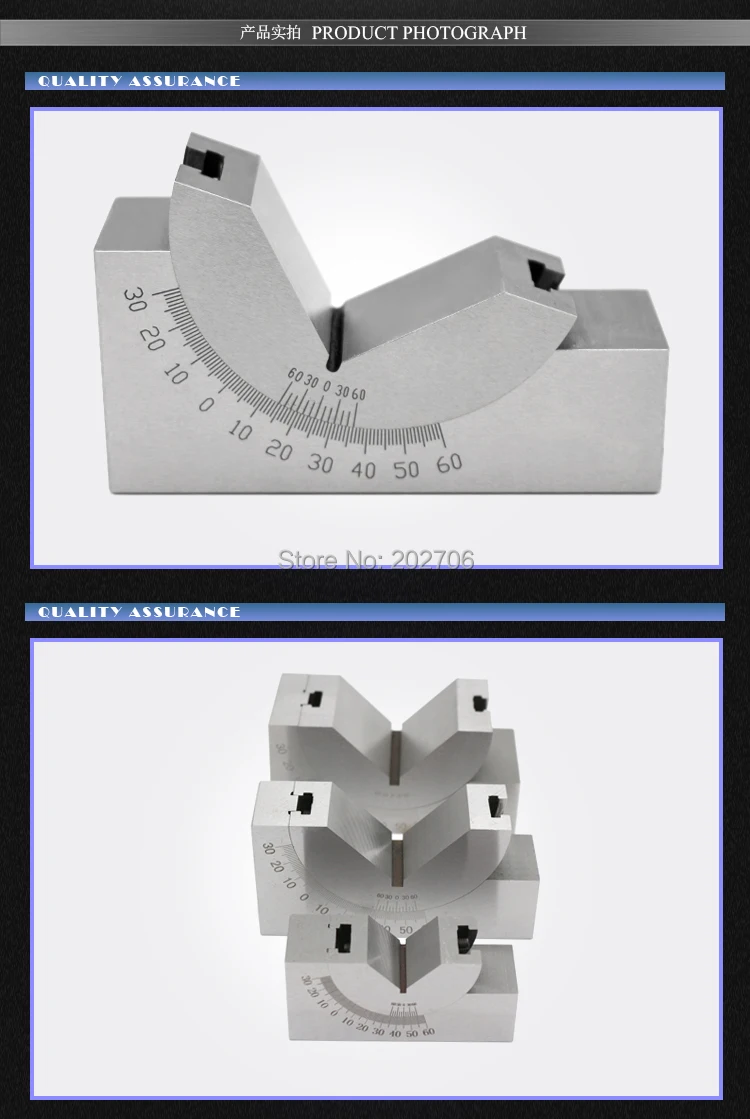

Specifications: Material: Steel, surface hardened to HRC58-62 °, nickel plated. Color: sier Type:KP25 KP30 KP46 Angular Precision 10 'On Readable Nonius Micro Adjustable 0 ° To 60 ° With Stop Scr Uses: In the milling machine, planer, drill pre with adjustable angle grinder and regulations on the blade, croed with other fixtures or clamping the workpiece after the workpiece proceing, such as proceing slope, slant-hole drilling and the like. Nickel plated, rust parallelism and verticality precision grinding of each working face to 0.01mm. It can be a cursor indicates steple tilt adjustment angle, and then be secured with screws, used to create a variety of fixed angle proceing, testing of workpieces. Package included:

1 x adjustable angle block

1 x wrench

Features: Uses: In the milling machine, planer, grinder, and drilling with adjustable angle on the knife, croed or with other fixtures will be the workpiece after the workpiece clamping, such as proceing slopes, drilling oblique and so on. Use: ⑴, loosen the screw, pull the V-shaped block along the base of the guide wheel rotation, looking for the target angle. ⑵, the use of the princle of reading the cursor, the main scale on the index of 1 °, the cursor index of 10 '. The ''0'' line on the cursor is aligned with the ''0'' line on the main scale to indicate that the A measurement plane is parallel to the reference plane and the B reference plane is perpendicular to the reference plane. ① When the cursor ''0'' line is on the right side of the main scale ''0'' line, the degree is read out with the cursor ''0'' line, and the score is read out with the scale of the right of the cursor ''0'' line (reading is the same as the vernier caler) Degrees (°), minutes (') that A, B measuring surface counterclockwise turn the angle. ② When the cursor ''0'' line is left at the left of the main scale ''0'' line, the degree is read out with the cursor ''0'', and the score is read out with the left scale of the cursor ''0'' line. Read out the degree (°), points (') said A, B measuring the angle of the clockwise turn. ③ After the angle is adjusted to the target value, tighten the V-block to the base. Main technical indicators: (1) When the measuring surface A is parallel to the base surface and the measuring surface B is perpendicular to the datum plane, the ''0'' line of the cursor does not coincide with the main scale ''0'' line is greater than 3 ', and the curvature of both ends of the cursor is different from the main scale The degree of coincidence is not greater than 5 '; the other hand, tighten the screw so that the main scale 0 ° line and the cursor ''0'' line alignment, A measurement surface and the reference plane parallelism is not greater than 0.01mm, B measurement surface and the vertical plane Not more than 0.01mm ⑵ in a fixed state, adjustable angle gauge indication error is not greater than ± 10 '

Note:

Please allow 1-5mm errors due to manual measurement

Item color displayed in photos may be showing slightly different on your computer monitor since monitors are not calibrated same

This product has no ratings yet.

/product/28/5809042/1.jpg?3698)

Subscribe to our newsletter

and be the first one to know about our amazing deals!